Adjusting or Repairing the Sprint Paper Sensor

customer

Symptoms: Printer is looping in Auto System Maintenance. Printer stuck in reset service counter (only in more severe cases), other symptoms will include print head moving to the left before print and getting stuck.

Possible causes: Ink will leak down into where the carriage is located and will stain and cause errors when printing or powering up.

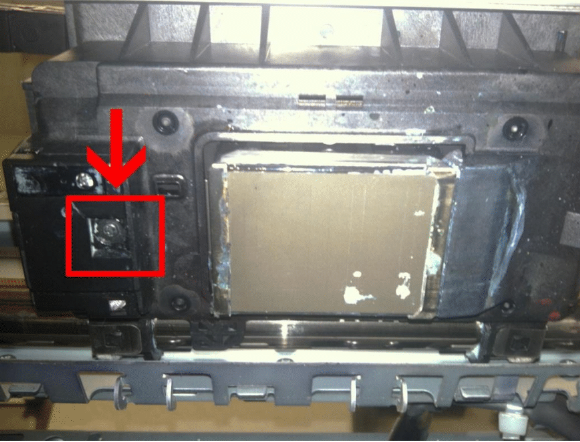

(1) Before starting, power down the printer and remove all cords. You will need a Phillips screw driver and a Antistatic wrist strap to prevent any static electricity from damaging the circuit boards. You will first want to release your print head to the middle. It will work best if you have mirror pointing up at the print head to get a better view of the screw located next to the nozzle plate (see picture below). Carefully unscrew it off.

Once you remove the screw, the sensor cap will come off and you should have something like this.

(2) Once the cap has been removed you will see one ribbon cable connected to a small board you see above. There will be another wire next to it that is not connected to anything. This is the sensor/ribbon cable we will be working with. Like mentioned earlier, ink will sometimes leak down in this area. Inspect the cable to make sure there is no ink on it. There should already be a piece of tape covering the end. (See picture below)

Carefully using a pair of scissors you will have to clip off a small portion of the cable.

Once you cut off the small piece cover the end end with a piece of tape carefully put back the small board back and screw the cap back on. (Note: be careful with the cables you don't want to kink one or get it pinched in-between the cap).

Here is a photo of the sensor already cut.