Epson Sure Color F2000 Review

Dean Armando

The Rumors Are True.

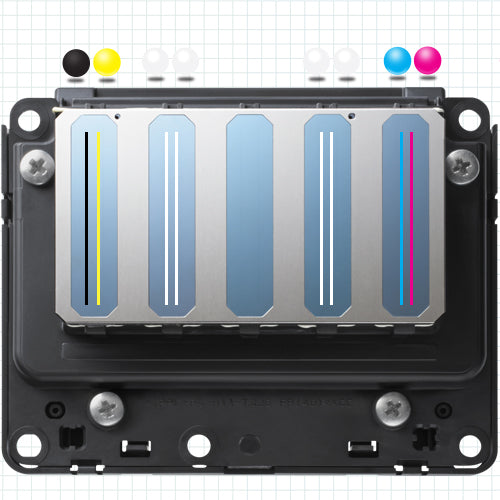

For over three years, Epson dedicated a team of mechanical, chemical, and software engineers to create an all-new imaging technology dedicated for printing directly to garments. This endeavor allowed us to rethink everything and ultimately design a garment printer the way it was meant to be.Introducing the Epson SureColor F2000 Series Designed using the latest advancements in performance imaging, like our purpose-built Epson PrecisionCore™ TFP®print head, along with our all-new garment ink technology – Epson UltraChrome DG – the SureColor F2000 series will become the new benchmark in high-performance garment imaging.The all-new Epson® SureColor® F2000 series was created with one objective in mind — making a killer T-shirt. Every aspect of these printers, from the printer mechanism to the ink delivery system, was purpose-built to deliver industrial-level production speeds, image quality, and reliability to redefine direct-to-garment (DTG) imaging.

- 5-color Direct-to-Garment Printer

- All new Ultrachrome® DG inks

- Revolutionary EPSON PrecisionCore® TFP® Print Head for extreme print quality and production speeds

- Maximum resolution of 1440 x 1440 dpi for white ink and 1440 x 720 for color inks

- Large garment imaging area up to 16\" x 20\"

- Designed for simple maintenance and high reliability

- Garment Creator imaging software included

- Free one-year of coverage under the Epson Preferred Protection Plan

- New pigment ink technology for cellulose-based garment imaging developed internally by Epson

- Compatible with both 100% cotton or cotton synthetic blends to 50/50

- Co-developed with the new print head technology to improve overall reliability

- Next-generation high-dispersion white ink technology reduce sedimentation and coagulation

- Very high white ink density, with a very natural white color

- Clean and bright color ink performance for outstanding finished garments

- Each cartridge has built-in ink filtering to better ensure ink entering the system is clear of contaminants

- An additional internal ink filter screens the inks a second time before entering the print head further improving print head life and reliability

- Robust garment durability

- The five color Epson prigment inks used in the Epson SureColor F2000 series printers, when applied to cotton fabrics, pass the requirements of the Oeko-tex Standard 100 for human ecological requirements of Class I products for adults, children and babies up to 36 months

- Advanced Thin Film Piezo (TFP) print chip core is only 1/1,000 mm thin

- Based on the Micro-Electro-Mechanical Systems process for an unparalleled level of manufacturing efficiency for consistent production quality

- Utilizes advanced piezo materials, delivering a higher-level of print head durability

- Co-developed with Epson UltraChrome DG ink technology for extreme garment imaging reliability

- Delivers precision ink droplet control for extreme print clarity and sharpness on garments

- 1,440 nozzles per inch dedicated to white inks for incredible print speeds with up to 720 nozzles per inch assigned to color ink

- Segmented color channels offers cleaning by color pairs, reducing ink waste and cleaning cycle time

- LED beam detection system automatically scans the surface of the garment prior to each imaging pass

- Protects the print head from garment strikes for improved reliability

- Scans the flat surface of garments up to 0.98\" in thickness

- Determines best platen height setting to achieve narrowest printing gap and highest imaging quality

- Works with all available platens: 4\" x 4\" sleeve, 10\" x 12\" small, 14\" x 16\" medium (included in-box) and 16\" x 20\" large

- Compatible with any 3rd party platen

- All new fabric wiper system cleans the print head surface with pristine material before every garment imaging job and before the print head is parked, increasing print head reliability

- Printer Maintenance Kit includes easily exchanged fabric wiper system, print head flushing pad, and print head capping station. Replaced approximately every 1000 garments, any trained operator can easily exchange all items in under 3 minutes

- Simple daily maintenance - 15 second manual shake of the white ink cartridges followed by an automatic white ink system recirculation

- Automatic white ink channel cleaning on power-on (default) or recommended manual nozzle check and clean color pairs as needed

- Garment Creator workflow software developed by Epson

- Very simple interface - quick learning-curve

- Available for both Apple®, Macintosh®, and Microsoft®, Windows® platform

- Raster-based software application supporting sRGB - TIFF (layered), PNG, JPEG, and BMP graphic files

- Easy-to-Use garment layout. Choose your platen size, place your image file, position, scale, rotate, etc. - then print

- Independent controls for color and white imaging

- Powerful color adjustment features

- Built-in Job accounting tools. Keeps track of ink usage by job for better cost estimation and expense tracking

- Additional levels of imaging capability are available from 3rd party RIP Workflows